Hardware

Lenovo leverages AI to combat e-waste

The refurbishment process is about to be transformed, writes YUGEN NAIDOO, Lenovo general manager for Southern Africa.

The ever-growing mountain of electronic waste (e-waste) poses a significant threat to our planet. A staggering 62-million tons of devices were discarded globally in 2024 alone, leaching harmful toxins into landfills and creating a pressing need for sustainable solutions. Alarmingly, less than 7.2% of the global economy currently operates under circular principles, and a mere 25% of worldwide e-waste is recycled.

At Lenovo, we are committed to minimising our environmental footprint and promoting a circular economy. One key initiative is our recently launched Lenovo Certified Refurbished program, offering high-quality, pre-owned devices. Now, we’re taking this a step further by harnessing the power of Artificial Intelligence (AI) to revolutionise the refurbishment process.

Traditionally, refurbishing devices involves manual inspection by engineers, a labour-intensive process that limits efficiency. Each device undergoes a meticulous examination to determine whether it can be repaired or harvested for spare parts. This not only requires significant manpower but also hinders the potential to scale refurbishment efforts.

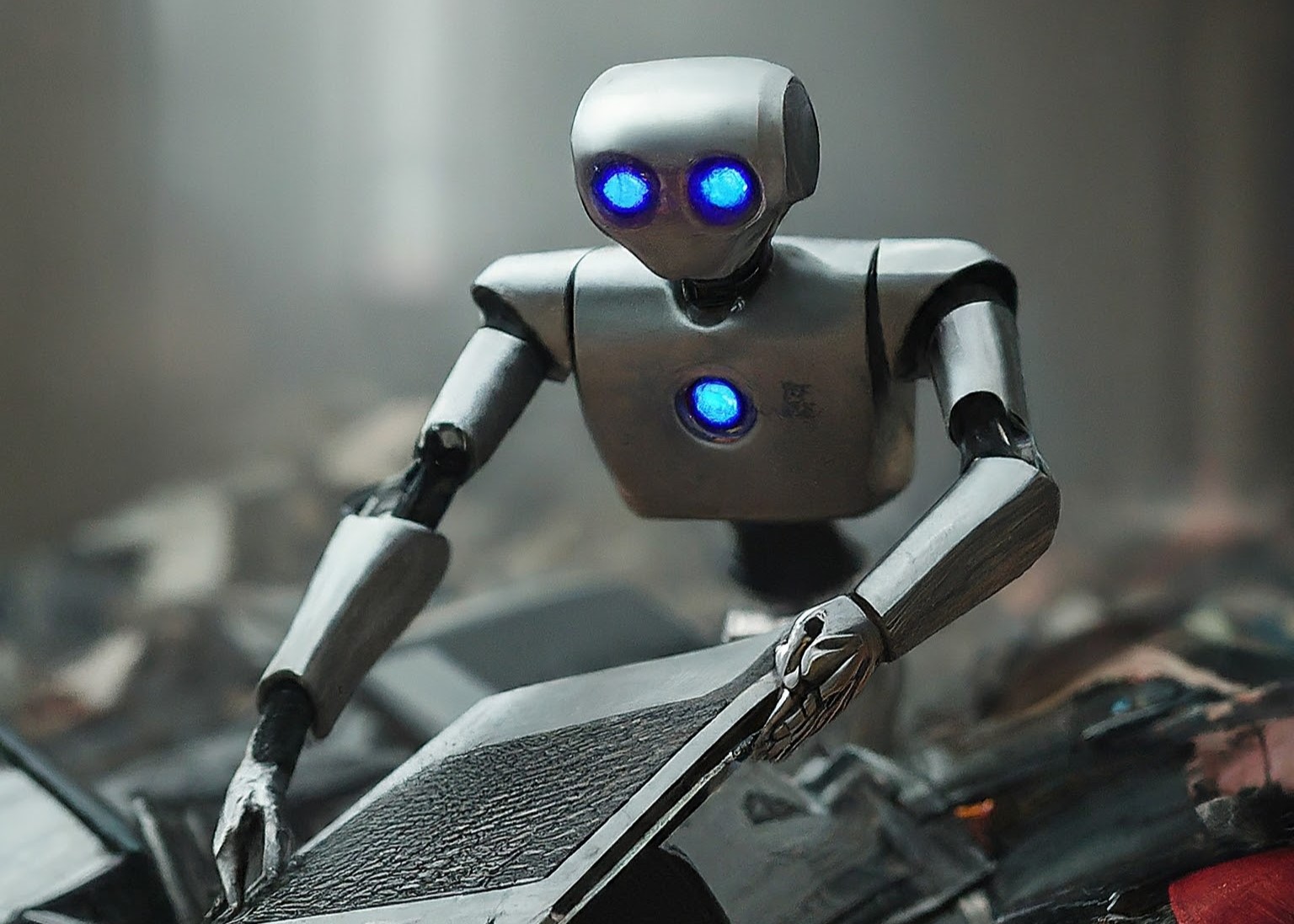

Recognising this challenge, Lenovo has developed a groundbreaking AI solution. This system utilises machine learning and computer vision technology to automate device inspections. By analysing images of internal components, AI can quickly identify faults, determine repair feasibility with a high degree of accuracy, and recommend the most effective procedures for our engineers.

This innovation goes beyond simply streamlining operations. By leveraging the vast amount of data generated during refurbishment, our AI solution offers valuable insights. Analysing this data allows us to identify common failure modes and assess component durability. Armed with this knowledge, we can refine future product designs, leading to longer-lasting devices and a significant reduction in e-waste generation.

The initial results of our AI-powered refurbishment program are nothing short of impressive. We’ve witnessed a staggering 116% increase in the average output units per hour for refurbished devices. This translates to a significant boost in our ability to process used devices and offer them a second life. Furthermore, this initiative has yielded significant cost savings of $100,000 annually associated with smartphone refurbishment alone. These savings allow us to reinvest in sustainable practices and further develop our AI capabilities.

While still in its early stages, this initiative holds immense potential. The ability to glean valuable insights from the refurbishment process paves the way for a future where devices are designed for longevity and repairability. This shift towards a circular economy is essential for ensuring a healthier planet for generations to come.

By pioneering AI-powered refurbishment, Lenovo is demonstrating its commitment to environmental responsibility. This innovative approach sets a new standard for the industry, paving the way for a more sustainable future where e-waste is minimised, and resources are maximised through a circular economy.