Picture This

Why the world will continue to print

Multiple factors make printing vital to organisations around the globe, writes YUDHEER HARBHAJUN, office automation sales manager at Epson SA.

It’s no surprise that a business famous for its printers says the world will continue to print. But it’s worth exploring why we believe this with such conviction when digitalisation continues to revolutionise every sector within industry.

In short, printing in the form most people will think of is here to stay. But there’s far more to printing than just ink on a page. There are multiple factors making it increasingly vital to organisations around the globe, with many leveraging our printhead technology that has the capability to print using almost any liquid or substrate.

Printing has no limits

Print has become highly intelligent. There have been huge advances in bio printing where organic and living materials can be produced for medical procedures, research, training and testing, in addition to developments in printing textiles, packaging, circuit boards and metals.

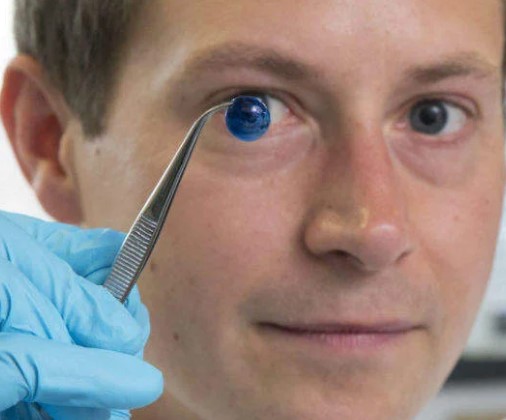

Across the world, exciting developments are taking place in healthcare. For example, 3D printing is already being used to print human organs. UK scientists have used stem cells to print human corneas. The proof-of-concept research for the 3D-printing technique saw human corneal stromal cells being taken from a healthy donor cornea and then mixed with alginate and collagen to create a ‘bio-ink’ solution that could be printed. Using a low-cost 3D bio-printer, the bio-ink was successfully printed in concentric circles to form the shape of a human cornea in less than ten minutes.

But it’s not just the healthcare industry that’s making waves. The use of 3D printing for the creation of foods has moved into the spotlight over the last few months as it continues to expand steadily. Recently, international deep-tech food company Steakholder Foods Ltd announced the release of a new, 3D printed meat cut called Omakase Beef Morsels. The richly marbled structured meat product is the first of its kind and was created using a specific 3D-bioprinting technology, inspired by the famous Japanese Wagyu beef.

Not only is this technology highly innovative. It also offers a solution to some of the pressing environmental issues that the world is facing. Currently, industrialised meat farming is one of the biggest contributors to climate change but in this instance, slaughter-free food removes the need to raise animals for the consumption of meat products. In turn, this will help to reduce the food industry’s impact on the environment and make food production more sustainable.

A new era for industrial printing

In contrast to traditional methods, digital printing has accelerated in recent years as the capabilities for packaging, textiles and labelling have expanded. Digital printing technologies are by nature more sustainable than traditional analogue alternatives, and offer a way forward towards clean, efficient, profitable, localised manufacturing.

While digital printing was previously adopted to improve quality and save on time and resources, organisations are now also making the switch because of positive impacts on the supply chain. As a result, nearshoring has become a recognised benefit of digital printing as it streamlines the entire production process, enabling products to be produced on-demand. In fact, according to a McKinsey & Company survey, 71 per cent of clothing and fashion companies expect to raise their nearshoring share by 2025.

When looking at the fashion industry specifically, a major factor driving the adoption of digital printing is the use of sustainable practices, including water efficiency and reduced chemical wastage. When compared to traditional analogue systems, which are heavy on water and energy consumption, digital printing systems reduce unnecessary waste. In fact, digital textile printing can save as much as 95 per cent of industrial water usage, while energy consumption can be reduced by 75 per cent – leading to the minimum use of resources.

Through shortened supply chains, on-demand production and nearshoring, which are all possible because of digital printing, organisations can improve their environmental footprint, as well as their efficiency, quality and costs.

Commercial printing goes green

And while printing now means much more than just office documents and photos, there will always be a need for paper alongside digital media. In fact, 55% of respondents in a recent study said they’re more productive and retain information better when working with paper. Fewer than 20% preferred digital documents. This means printing is still important, and in general, printed materials are unlikely to go away anytime soon.

But there is pressure to boost sustainability and while office printing may not immediately be thought of as a positive in this context, carful technology selection can have a major impact on sustainability goals. In the last few years, commercial inkjet products have been gaining traction as they use up to 90 per cent less energy and create less waste than equivalent laser printers.

Epson inkjet printers use Heat-Free Technology which means heat is not required in the ink ejection process. Instead, pressure is applied to the Piezo element, which flexes backwards and forwards firing the ink from the printhead. In contrast, laser printers need to heat a fuser to enable printing, which results in significantly more energy consumption, CO2 production and increased costs.

Many companies are investing in inkjets to improve sustainability. According to IDC data, the business inkjet market is expected to grow at +7.2 per cent, per annum, contrasting with a decline of -1.1 per cent year-on-year in demand for laser printing. Leaders who are not already considering the change could secure a quick win by doing so.

Home printing is on the rise

Hybrid working is here to stay, and home printing volumes have risen as a result. So too has awareness around ink subscription services. In fact, research has revealed that 63 per cent of people are printing more at home than they were a year ago, while 56 per cent say they need to print documents for signature or archive.

To unlock the benefits of hybrid working, organisations need to address home worker print requirements. Now, more than ever, certain factors are bringing these requirements to the fore, from spiralling energy costs, to higher expectations when it comes to the standard of living and working.

Chosen carefully and used well, printers can help cut costs, reduce energy consumption and improve outcomes in many ways – from sustainability and workflow, to reducing lost hours of work.

Long live printing

Printing has an exciting future, especially as organisations continue to embrace innovative technology and materials that go beyond the imagination. The fact that we continue asking whether the printing industry is dying is a testament to its future.

From the humble printing press to printing human corneas – print is thriving.